Is there an unusual squeak, knock, or thud coming from your vehicle? It might be a sign of a worn tie rod end! Fortunately, replacing this component is a straightforward process and doesn’t entail significant expenses.

When is it necessary to replace the tie rod end?

The tie rod end serves as a connection between the steering knuckle, tie rod, and steering gear. Over time, like any other automotive part, the tie rod end experiences wear and tear, necessitating replacement.

Neglecting the proper maintenance of the tie rod end can have serious consequences. A deteriorated tie rod end can disrupt wheel alignment, adversely affecting tire lifespan. In extreme situations, a worn tie rod may even lead to a wheel detachment while driving, resulting in potentially tragic outcomes.

Quick diagnostics for the tie rod end

Common indicators of a malfunctioning tie rod end include:

- Unusual sounds emanating from the front wheels (knocking, thudding, squeaking), audible even when the vehicle is stationary.

- Looseness, jerking, and vibrations in the steering system are perceptible through the steering wheel.

- Decreased driving comfort, such as compromised bump absorption and a weaker response to steering wheel movements.

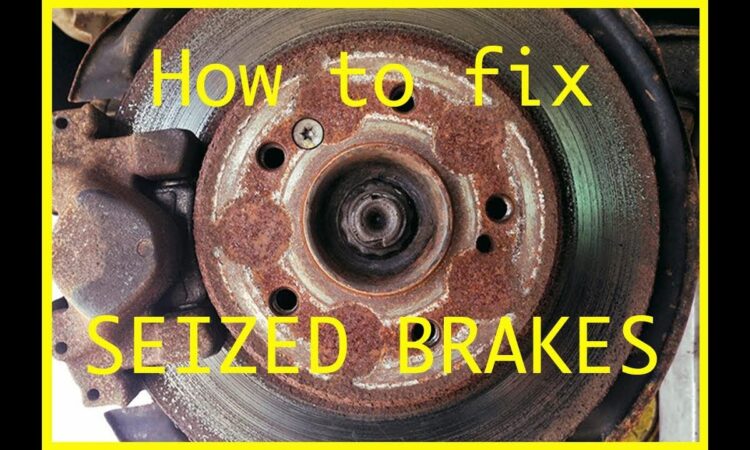

If any of these symptoms are observed in your vehicle, it is advisable to check for potential looseness in the tie rod end. To do this, elevate the car using a jack and then attempt to move the wheel sideways while holding the joint just behind the brake disc. If there is noticeable looseness, it indicates that the tie rod end is likely worn and requires replacement.

Replace your tie rod end by yourself!

Changing a worn-out tie rod end is a manageable task that you can accomplish in your own garage. With basic tools, a spare 30-60 minutes, and a new tie rod end, you’ll be all set. Having a specialized steering rack wrench on hand will also prove helpful.

Here’s a step-by-step guide:

- Loosen the Wheel Bolts:

Start by loosening the bolts on the wheel with the problematic tie rod end. Then, lift the car using a jack to facilitate wheel removal. Unscrew the wheel and position it under the car as a safety precaution in case the jack fails. Clean the tie rod joint using a wire brush and rust remover. - Remove the Tie Rod End:

Once the rust remover has worked its magic, begin disassembling the tie rod end. To ensure accurate replacement, mark the spot on the rod where the tie rod end starts or count the revolutions while unscrewing the old one. The new tie rod end should be screwed in to the same length. Proceed to loosen the lock nut on the rod and then unscrew the nut at the end. Gently tap out the end without screws using a hammer, taking care with the screw thread. - Steering Rack Inspection and New Tie Rod End Installation:

With the worn part removed, inspect the steering rack for any signs of wear by giving it a few tugs. There should be no noticeable looseness. If something feels off, other components of the steering system may require replacement. Finally, install the new tie rod end, screwing it in to match the length of the previous one. Fasten the screws securely. After completing the job, be sure to visit a professional service to check the wheel alignment.